Alternative Septic System

We have installed an alternative septic system in our "weekend project"

(our barn/office). It has been in full operation since November 2010, and is functioning

very well. Please see most recent photos and information at the bottom of this page.

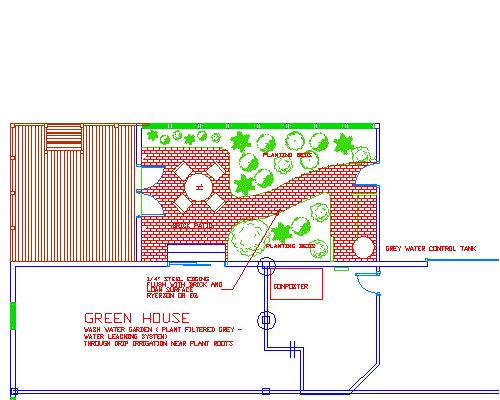

Feb, 2011 photo of greenhouse planting beds.

Background:

In Massachusetts, a building's use is restricted by the amount of sewage that is produced

and the ability of the surrounding land to absorb the septic waste through a leaching field.

A single family home's septic sytem must be designed to handle 110 gallons per day per bedroom,

and an office has to be able to handle 75 gallons per day per 1000 square feet of area.

In our case, we have a 3 bedroom system that legally handles our 3 bedroom house, but our

intention to add office space would theoretically overload the system.

The solution for our barn office was to work with the MA Department of Environmental

Protection and the Berlin Board of Health to install a composting toilet and a greywater

leaching system. The composting toilet (Phoenix Model #R-200) is an accepted technology

in Massachusetts and has no regulatory issues with its installation. The greywater leaching

system on the other hand is an innovative alternative technology. It required State DEP approval,

and will be monitored as a pilot program.

Composting toilet is a stand alone product with its own piping and venting.

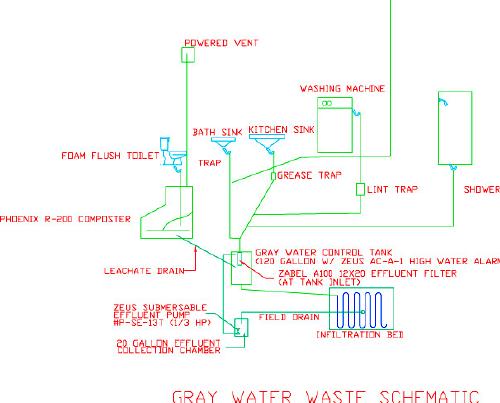

The washing machine (Fisher & Paykel EcoSmart, approx. 12 gallon per load), bath sink

(1.5 gal/min), kitchen sink (4 gal/full basin), shower (20 gal/10 min.), all drain

through conventional plumbing to a grey water control tank, and then to the infiltration

bed, where the plants treat the grey water.

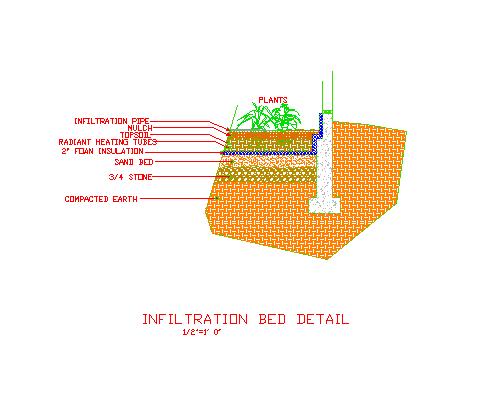

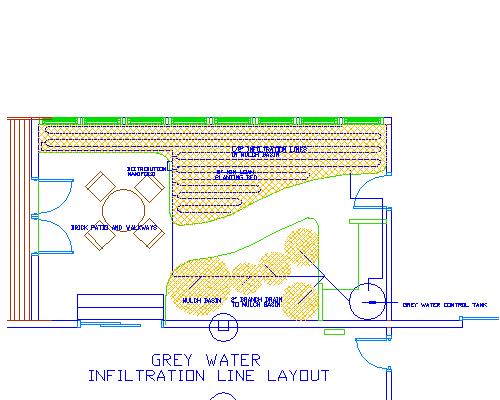

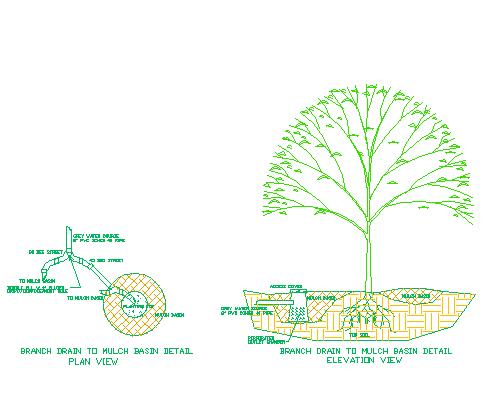

Infiltration pipes distribute the grey water through a mulch basin and beds where it

percolates into the root system of the plants.

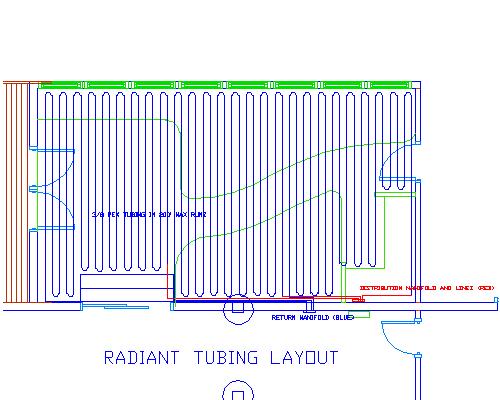

First, two inches of foam is placed on the compacted earth. Then 8 x 8 welded wire fabric

(rebar mat) is placed over it. We then attach Pex radiant heat tubing to warm the floor

of the greenhouse. Supplemental heat will be supplied to the greenhouse using a commercial

grade steel finned baseboard, recycled from a job in Newton.

Both mulch beds and basins are constructed so that varying plant sizes can be used to

optimize the system.

The final layer is the finished floor. A patio and walkway are built using Ryerson steel

landscape edging to separate the planting beds from the hard area.

A typical mulch basin detail for an ornamental tree.

The greenhouse is built off of the back of our barn,

which serves as our shop with office above.

Interior greenhouse, framed and stone dust floor added and leveled.

Next a layer of foam was added for insulation, and

radiant heat tubing was installed above (not shown).

During the winter, our mason Jeff Baer built this beautiful walkway.

After the DEP review of our plans, we were asked to line the planting beds with an

impermeable membrane. We had to remove most of the loam, and take out some of the walkway in

order to do that. This made the system "zero discharge" in that none of the grey water

escapes the system. We also installed drains (white caps in photos) so that when the beds get

saturated, the water is then drained into a sump pump and recirculated back into the plant beds.

We had to dig deep under the foundation of our existing barn to put in the sump pump,

so that it would be below the plant beds. Carl did almost all the work, but only Sara

was small enough to get in and do the last digging.

Sump pump installed.

After completing the rubber lining, we filled the plant beds with a combination of

peat moss,vermiculite, loam, and compost. Peat will hold moisture for the plants, vermiculite

keeps the soil from compacting, compost adds nutrients, and loam fills it out. The first three

was an idea borrowed from the "Square Foot Gardening" method by Mel Bartholomew. Then we laid

out the dousing lines--the irrigating lines that bring the grey water to the planting beds.

After several attempts, we finally were able to pitch the lines to enable

water to get to all areas of the beds. Initially there were some areas that were

more heavily watered, which was not too much of a problem, because of the different

watering needs of different plants. However, we later added ball valves to each of the

lines, and now can control how much water goes to each of five areas.

The grey water leaching field is complete, and first plants are in.

Most plants love the greenhouse and the grey water "watering", with only a few exceptions.

We started with plants from our summer garden (low cost, easy to replace if they didn't work well).

Geraniums did very well, and multiplied from eight plants to approx. fifty (using cuttings

and replanting). We've lost only a few plants to bugs and over-watering, but the surprise is how

tolerant most plants are to water temperature, fluctuations, soaps and detergents.

We were not achieving balanced dosing of the planting beds, so we increased our infiltration lines from

two to five. The five lines now come off a common manifold, and each line is controlled by a ball valve

allowing us to increase or decrease effluent flow as desired. We also installed a Schrader valve

(similar to a car tire valve) so that in the future we could use compressed air to clear a line if needed.

Winter 2011. We added ornamental banana trees and the water absorption has been greatly increased.

The beds initially absorbed in the 30-35 gallon per day range, but now absorb 50 gallons per day, in winter,

when the evapo-transporation rates are most challenged.

Thank you for visiting our "Alternative Septic System" page

If you have any questions, comments, or suggestions, please

contact us:

Warren Design Build

268 West Street

Berlin, MA 01503

Tel:/Fax (978) 838-0022

Email:carl@warrendesign.com